Introduction:

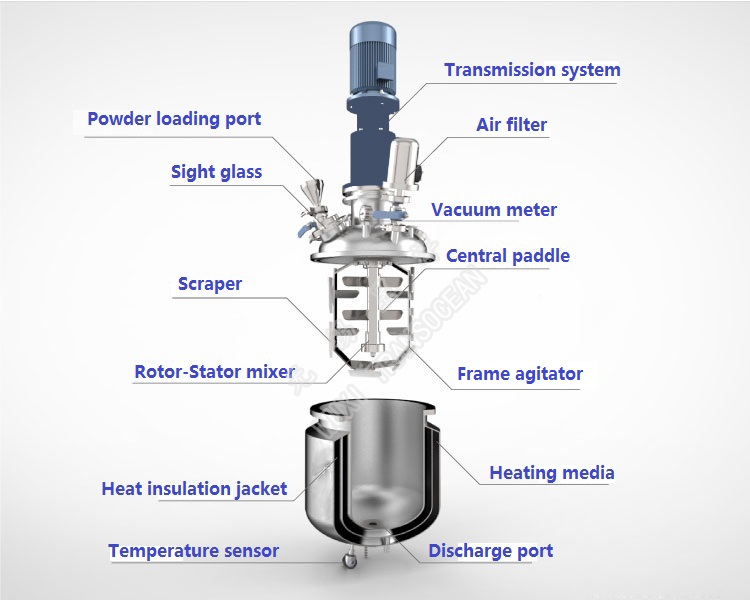

l TRANSOCEAN® RJZ series vacuum emulsifying homogenizer is composed of a set concentric contra mixing unit (impellers on the central shaft and wall scraper and frame type mixer with PTFE scrapers around the central shaft) and a rotor stator mixer. The contra mixing unit can be installed either on a rack lifted/lowered hydraulically or on a fixed platform. The rotor stator mixer can be installed either on top of the liftable rack coaxially with the hollow shaft of the impeller or beneath the bottom of the mixing tank. Raw materials are prepared in the water phase material preparation tank and oil phase material preparation tank by a high speed disperser and then be sucked into the mixing tank by the negative pressure created by the vacuum equipment. Materials in the mixing tank are pressed downwards by the impellers towards the rotor stator mixer for shear, emulsifying and homogenizing. The vacuum equipment will form vacuum in the mixing tank simultaneously while mixing. A rotary pump is available as an option for the circulation of the material between the bottom and the top of the mixing tank. Finished products can be pumped out from the bottom or discharged after the mixing tank is dumped by more than 90 degrees.

Applications:

TRANSOCEAN® RJZ series vacuum emulsifying homogenizers are applicable for production of creams, emulsions, gels, shower gels, mascara, gel, glycerins lotions, balms, shampoos, wax, toothpaste, ointments, dental composites, colloids, silicone oil, leather oil, emulsion explosives, chocolate, condensed milk, yogurt, syrup, concentrated fruit juice, jam, ice cream, yeast slurry, meat slurry, jelly, sizing agent, defoaming agent, etc.

Characteristics:

Combination of central paddle agitator, frame agitator with scraper and rotor-stator mixer

Material of wetted parts: S.S.304/S.S.316L/S.S.321

Materials are mixed, sheared, compressed folded and pushed towards rotor-stator mixer by paddle agitator and frame agitator which rotates in opposite directions

Inside wall of mixing tank is swept by PTFE scrapers on frame agitator

Materials in tiny gap between rotor and stator are subject to the combined function of shearing, centrifugal squeeze, friction, impact, tearing and turbulence generated by strong momentum resulting from high velocity and high frequency mechanical effect of rotor.

Paddle agitator & frame agitator can run separately from rotor-stator mixer

Air bubbles are removed simultaneously from materials by vacuum equipment during mixing period

Lifting of mixing head: by electrical/hydraulic cylinder

Easy to maintain, clean and change product

Finished products characterize great homogeneity (200 nm to 2μm), perfect fineness, charming gloss and excellent ductility.

Size of mixing tank:

5L, 10L, 20L, 30L, 50L, 100L, 150L, 250L, 350L, 650l, 800L, 1300L

Option:

Button type control panel or Touch screen control panel