Ø Introduction:

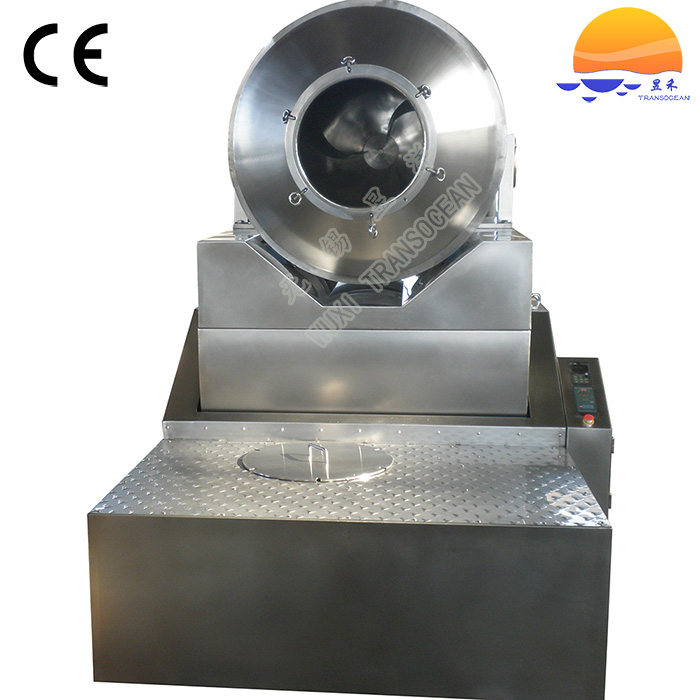

A two-dimensional motion mixer refers to a mixer whose drum performs two-directional movements simultaneously. The vessel swings with the swing frame while rotating around its own axis. The two-dimensional mixer is mainly composed of a rotating drum, a swing frame and a rack. The drum is mounted on a swing frame, supported by four rollers and axially positioned by two blocking wheels. Two of the rollers are connected to the power system, transmitting power to the drum, which drives the drum to rotate. The swing frame is mounted on the rack via the bearing assembly, and is driven by one set of crank and swing rod mechanisms on the rack. The materials in the drum are rotated and flipped by the drum, and swings back and forth with the drum. Under the combined effects of these two movements, the materials can be fully mixed in a short time. Optional vacuum loader and interface are available for fast loading to save operation time. The mixer is widely used for mixing powders and granules.

Ø Applications:

The two-dimensional motion mixer is applicable for the mixing of various solid-phase materials in the industries such as pharmaceutical, chemical, food, dye, feed, fertilizer and pesticide.

Ø Features:

l The materials in the drum participate in two-dimensional movements.

l Compact structure

l Very low noise

l The outlet is deviated from the center line of the drum.

l Meet GMP requirements.

Ø Advantages:

l High mixing efficiency

l Reliable operation

l Small footprint

l It is easy to discharge the products and easy to clean the mixer.

Ø Benefits for you:

l Save investment in equipment and plant.

l Cut down production costs

l Reduce equipment maintenance costs

Ø Technical specifications:

Model | Total volume(L) | Max. working volume(L) | Max. load(KG) | Main shaft speed (rpm) | Installed power (KW) | Outline dimension(mm) | N.W.(KG) | |||

L | W | H | H1 | |||||||

DD-10 | 10 | 6 | 3 | 85 | 0.021 | 400 | 310 | 450 | 395 | 15 |

DD-30 | 30 | 18 | 9 | 61 | 0.19 | 580 | 540 | 900 | 700 | 60 |

DD-60 | 60 | 36 | 18 | 50 | 0.4 | 730 | 700 | 1100 | 990 | 115 |

DD-150 | 150 | 90 | 45 | 37 | 1.15 | 1050 | 800 | 1450 | 1340 | 190 |

DD-300 | 300 | 180 | 90 | 30 | 1.15 | 1350 | 900 | 1550 | 1400 | 340 |

DD-600 | 600 | 360 | 180 | 23.6 | 3 | 1640 | 1170 | 2050 | 1910 | 1150 |

DD-800 | 800 | 480 | 240 | 19.8 | 3 | 1950 | 1320 | 2150 | 2000 | 1600 |

DD-1000 | 1000 | 600 | 300 | 19.8 | 3 | 2980 | 1300 | 1894 | 1766 | 1700 |

DD-1500 | 1500 | 900 | 450 | 16.2 | 4.4 | 3195 | 1500 | 2150 | 2008 | 2000 |

DD-2000 | 2000 | 1200 | 600 | 16.2 | 7.4 | 3305 | 1660 | 2255 | 2120 | 2600 |

DD-3000 | 3000 | 1800 | 900 | 13.8 | 11 | 3800 | 1860 | 2570 | 2420 | 3500 |

DD-4000 | 4000 | 2400 | 1200 | 12.8 | 13 | 4100 | 2010 | 2755 | 2550 | 4100 |

DD-6000 | 6000 | 3600 | 1800 | 11.2 | 18.5 | 4965 | 2280 | 3172 | 2935 | 6100 |

DD-8000 | 8000 | 4800 | 2400 | 10.4 | 22 | 5200 | 2500 | 3655 | 3200 | 7900 |

DD-10000 | 10000 | 6000 | 3000 | 9 | 30 | 5500 | 2600 | 3750 | 3400 | 9500 |