²Introduction:

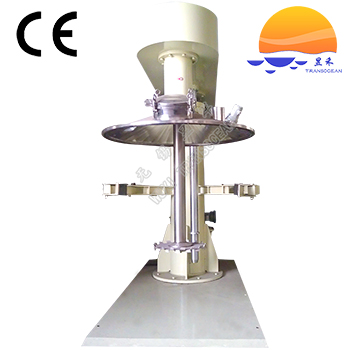

TRANSOCEAN® high speed dispersers are widely used for dispersing of solids into fluids in the production of paints, coatings, color pastes, dyes, adhesives, inks, etc. The disperser head containing a saw-tooth type dispersing disc can be raised or lowered hydraulically for loading/unloading of a material tank. It is convenient to clean the disperser and change products. Various mixing tanks can share one mixer. Explosion proof high speed dispersers are suitable for use in hazardous areas. Buttons are provided on the control panel to realize start, stop, acceleration or deceleration of mixing disc, lifting or lowering of mixing head. An inverter is available in the electric cabinet for speed adjustment from 0 to design speed. The classic saw-tooth dispersing disc runs at a tip velocity up to around 25m/s and creates a vortex around the dispersing shaft and generates tremendous shear force to the materials to process. Wetting and dissolving of powders will be achieved in a short time. With the hydraulic lifting system the mixing assembly can be raised to a certain position so that the material tank can be loaded or unloaded. A mechanical clamping arm for fixing of material vessel is supplied as an option. The floor-standing type high speed dispersers and the platform type high speed dispersers are available as an option.

² Features:

l Dispersing disc: saw-tooth shape

l High efficiency of dispersion and dissolution of liquid-liquid / liquid-solid materials

l Material of wetted parts: S.S.304/S.S.420/Chrome plated #45 steel

l Dispersing head lifting/lowering mode: by hydraulic cylinder

l Dispersing head lowering speed: adjustable with regulating valve

l Easy to clean and change product

² Technical specifications:

Model | FL1.5 | FL4 | FL5.5 | FL7.5 | FL11 | FL22/FX22 | FL37/FX37 | FL45/FX45 | FL90/FX90 | |

Main motor power(KW) | 1.5 | 4 | 5.5 | 7.5 | 11 | 22 | 37 | 45 | 90 | |

Dispersing shaft speed(r.p.m.) | 0-1450 | 0-1450 | 0-1450 | 0-1450 | 0-1450 | 0-1450 | 0-1200 | 0-1200 | 0-1000 | |

Speed control mode | By inverter | |||||||||

Dispersing disc dia. (mm) | 150 | 200 | 230 | 230 | 250 | 350 | 400 | 450 | 600 | |

Lifting/lowering stroke(mm) | 600 | 800 | 800 | 900 | 900 | 1200 | 1200 | 1600 | 1600 | |

Hydraulic motor power(KW) | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 1.1 | 2.2 | |

Tank volume(L) | 50 | 200 | 200 | 300 | 400-600 | 600-1000 | 1000-2000 | 1000-2500 | 5000 | |

Weight(Kg) | 120 | 400 | 500 | 700 | 800 | 1500 | 1700 | 2100 | 2600 | |

External dimension (mm) | A | 1400 | 1700 | 1750 | 1750 | 1750 | 2200 | 2200 | 2600 | 2700 |

B | 940 | 1300 | 1720 | 1800 | 1800 | 2100 | 2100 | 2700 | 3000 | |

C | 515 | 600 | 830 | 830 | 900 | 1100 | 1300 | 1400 | 1600 | |

W | 350 | 540 | 650 | 650 | 650 | 900 | 900 | 1000 | 1500 | |

² Remarks:

l Floor mounting type (FL) and Platform mounting type (FX) are alternative.

l Movable tank or platform type tank shall work with HSD

l Technical data of each model can be customized.

l High power HSD (up to 315KW) not listed can be customized.

²Optional parts:

l Belt type clamping arm or mechanical scissor type clamping arm

l Tank lid