² Characteristics:

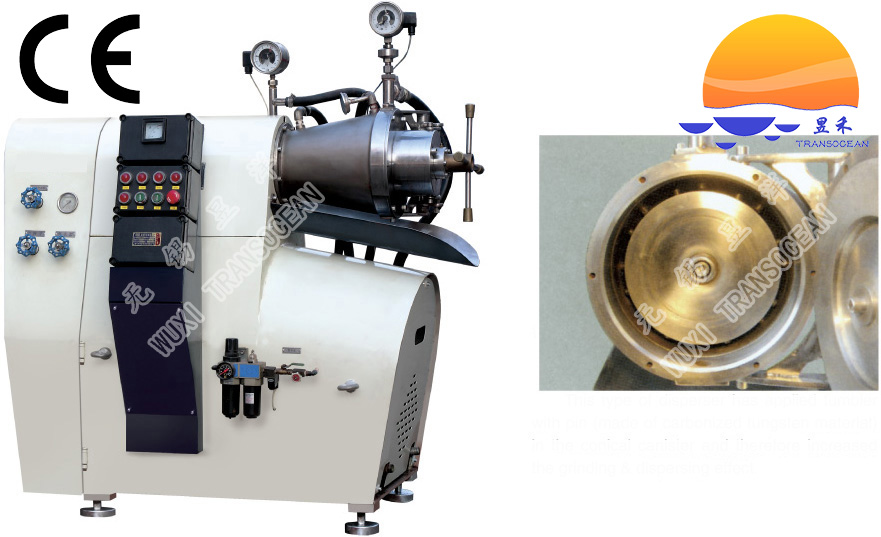

l Interlaced array of high rigidity alloy grinding pegs on internal surface of grinding chamber and external surface of rotator shall provide high impact and shear to grinding media and reduce dead area significantly

l Material of grinding chamber and rotor: S.S.440C

l Loading coefficient of grinding beads can be adjusted with piston type adjusting mechanism at end of grinding chamber according to various production processes

l Double face mechanical seal is adopted to ensure reliability

l Sealant circulating in mechanical seal driven by pneumatic diaphragm pump is compatible with solvent in grinding media to avoid pollution to grinding media

l Cooling jacket outside sealant tank and cooling jacket outside grinding chamber are adopted to cool down mechanical seal and grinding media.

l Cooling system is adopted in hollow main shaft to cool down grinding media.

l Adjustable range of pressure limit switch at material inlet: 0-6 bar

l Adjustable range of temperature limit switch at product outlet: 0-100℃

² Fault alarm on control panel shall be activated in such cases:

l Pressure of cooling water in cooling jacket: too low

l Working pressure in grinding chamber: too high

l Temperature at product outlet: too high

l Circulation of coolant for mechanical seal: not work

l Level of coolant for mechanical seal: too low

l Motor load: overload

² Application:

l Wet grinding of offset printing ink, fluorescent ink, UV ink, rotogravure ink, letterpress ink, concentrate paste and other medium/ high viscosity materials

² Technical data:

Model | ZWS-6 |

Main Motor Power (KW) | 22 |

Main Shaft Speed (r.p.m.) | 900 |

Capacity of grinding chamber (L) | 6 |

Output Capacity (L/H) | 30-350 |

Cooling Water Consumption (m3/h) | 1.3 |

Compressed Air Pressure (MPa) | 0.6-0.8 |

Grinding media | Φ1.0-1.8mm 94.50%+ ZrO2 Beads |

Material feeding | By diaphragm pump/gear pump/plunger pump |