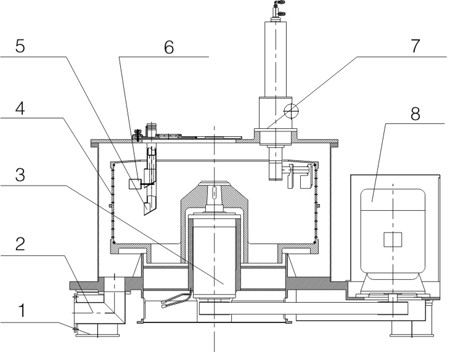

1.Damper 2.Drain 3.Shaft assembly 4.Drum 5.Loading pipe 6.Material level controller 7.Scraper assembly 8.Motor

Filter medium shall be loaded from loading port into the drum. By virtue of centrifugal force liquid in filter medium shall be drained out of centrifuge and solid shall be kept in drum. Scraper shall start scraping residual in drum and discharge it from bottom of centrifuge.

It is programmable to realize, and automatic loading, separation, washing, dehydration, discharge, etc. Local control and remote control is available.

It characterizes high degree of automation, large processing capacity, perfect separation effect, etc.

Counter-weight and high viscous liquid damper are adopted to absorb vibration.

No special foundation is required.

Comply with GMP sanitary standard.

Solid-liquid separation of suspension (solid particles ≥0.01mm in diameter) in chemical industry, light industry, pharmaceutical, food, metallurgical and other industries.

Item | PGZ800 | PGZ1000 | PGZ1250 | PGZ1320 | PGZ1500 | PGZ1600 |

Drum dia.(mm) | 800 | 1000 | 1250 | 1320 | 1500 | 1600 |

E. H. of drum(mm) | 400 | 450 | 500/630/800 | 630/800 | 750 | 800/1000 |

E. V. of drum(L) | 100 | 155 | 280/354/450 | 400/510 | 612 | 775/970 |

Max. Load(KG) | 140 | 210 | 380/480/580 | 520/660 | 825 | 1150/1300 |

Speed(r.p.m.) | 1200 | 1000 | 1000 | 900 | 850 | 800 |

Separation factor(Fr) | 645 | 560 | 700 | 598 | 606 | 573 |

Motor power(KW) | 7.5 | 11 | 18.5/22/30 | 22/30 | 37 | 37/45 |

N.W.(KG) | 2000 | 2600 | 4000/4200/4500 | 4500/4800 | 8000 | 9500/10000 |

Outline dimension(mm) | 1800*1300*1900 | 1950*1600*2000 | 2300*1800*2150 | 2300*1800*2400 | 2800*2100*2700 | 2980*2250*3000 |

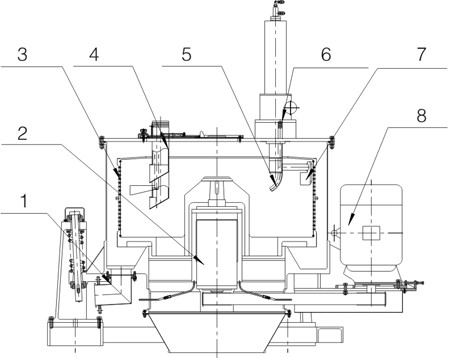

SGZ结构图

1.Drain 2.Drive assembly 3.Drum 4.Loading pipe 5.Rinsing pipe 6.Shaft assembly 7.Material level controller 8. Motor

Technical data:

Item | SGZ800 | SGZ1000 | SGZ1250 | SGZ1320 | SGZ1500 | SGZ1600 |

Drum dia.(mm) | 800 | 1000 | 1250 | 1320 | 1500 | 1600 |

E. H. of drum(mm) | 400 | 450 | 500/630/800 | 630/800 | 750 | 800/1000 |

E. V. of drum(L) | 100 | 155 | 280/354/450 | 400/510 | 612 | 775/970 |

Max. Load(KG) | 140 | 210 | 380/480/580 | 520/660 | 825 | 1150/1300 |

Speed(r.p.m.) | 1200 | 1000 | 1000 | 900 | 850 | 800 |

Separation factor(Fr) | 645 | 560 | 700 | 598 | 606 | 573 |

Motor power(KW) | 7.5 | 11 | 18.5/22/30 | 22/30 | 37 | 37/45 |

N.W.(KG) | 1800 | 2200 | 3500/3800/4200 | 4100/4500 | 7500 | 8500/9000 |

Outline dimension(mm) | 1800*1400*1960 | 1925*1555*2000 | 2400*1950 *2150/2400/2700 | 2400*1950 *2400/2700 | 2800*2100*2700 | 2990*2500 *3000/3200 |

Spray rinsing system

Nitrogen protection system

Material level controller

PLC

Hydraulic operation system

Auxiliary Pneumatic scraper

Wetted parts: S.S.304, S.S. 316L, S.S.321, titanium, Hastelloy, rubber lining, PE lining, Halar coat, etc.

Main shaft speed control mode: by inverter

Drain mode of rinsing liquid and liquid in filter media: through a shared drain or separate drains